In recent years, the demand for stylish and functional outdoor living spaces has surged, leading to a booming interest in pergolas. These elegant structures, once a niche luxury, have become a staple in gardens, patios, and backyards worldwide. Central to this trend is the rise of pergola factory, specialized facilities dedicated to the design, production, and distribution of these versatile outdoor enhancements. This article explores the burgeoning industry of pergola manufacturing, highlighting the craftsmanship, innovation, and trends driving its growth.

The Craftsmanship Behind Pergola Factory

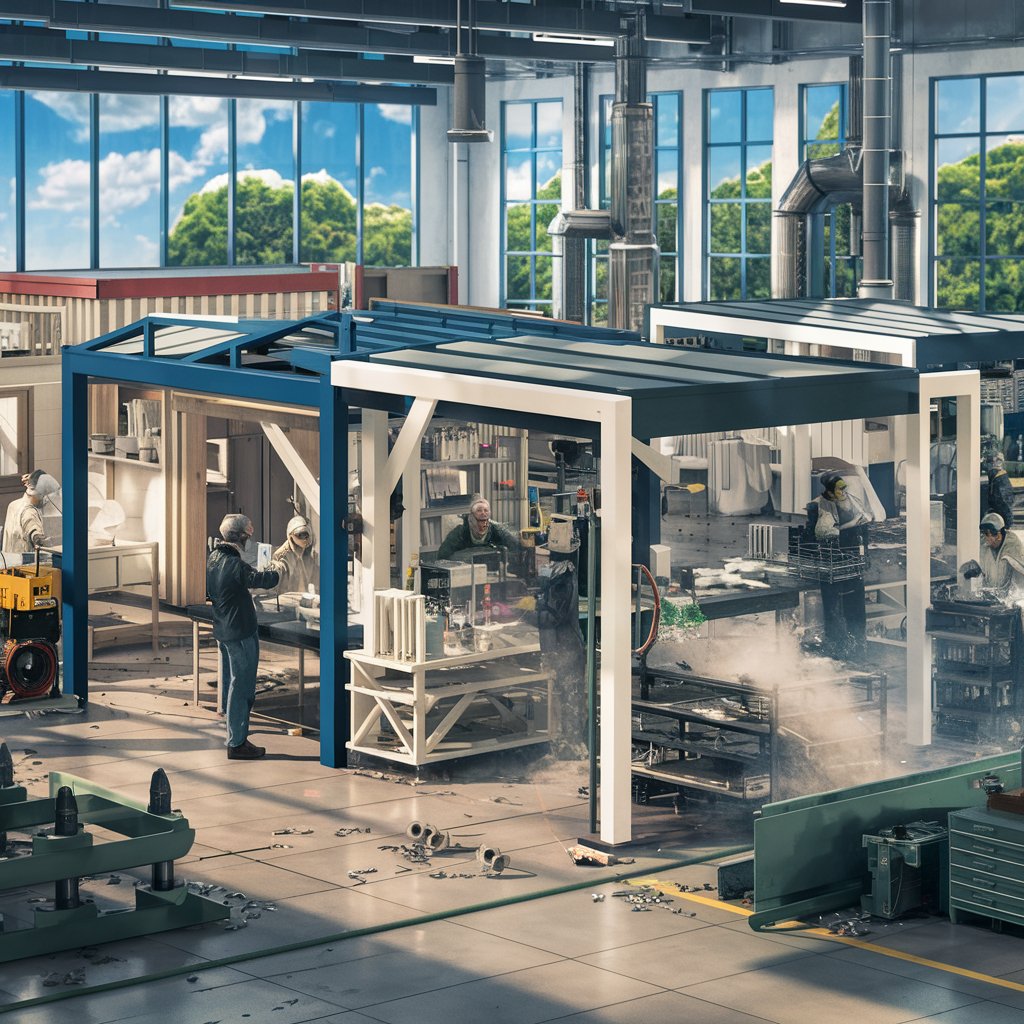

At the heart of any successful pergola factory lies a commitment to craftsmanship. These factories combine traditional woodworking skills with modern technology to produce high-quality pergolas that cater to various tastes and needs. Skilled artisans and carpenters work alongside engineers and designers to create structures that are not only functional but also aesthetically pleasing.

The process begins with the selection of premium materials. Wood remains a popular choice for its natural beauty and durability, with options ranging from classic cedar to exotic hardwoods. However, modern pergola factory also experiment with materials like aluminum and vinyl, which offer benefits such as low maintenance and increased longevity.

The woodworking craftsmanship in pergola factory is a blend of age-old techniques and modern advancements.

Artisans skilled in traditional joinery techniques work meticulously to ensure that each pergola not only meets high aesthetic standards but also provides structural integrity. This craftsmanship is evident in the detailed carving, precise cuts, and seamless joints that characterize high-quality pergolas.

In addition to traditional woodworking, pergola factory also employ advanced machinery to enhance precision and efficiency. Computer Numerical Control (CNC) machines, for instance, are used to execute intricate designs and ensure that each component is cut to exact specifications. This blend of handcraftsmanship and technology ensures that the final product is both beautiful and durable.

Innovation in Design and Technology

Innovation is a key driver in the pergola manufacturing industry. Factories employ advanced design software to create customizable plans that meet specific customer requirements. This software allows for precision in measurements and cuts, ensuring that each piece fits together seamlessly during assembly.

One of the most significant innovations in pergola manufacturing is the use of 3D modeling software. This technology allows designers to create detailed digital representations of pergolas, enabling customers to visualize their custom designs before production begins. This not only enhances the customer experience but also reduces the likelihood of errors and revisions during the manufacturing process.

Moreover, many factories are incorporating eco-friendly practices into their production processes. Sustainable sourcing of materials, energy-efficient manufacturing methods, and the use of recyclable components are becoming standard in the industry. This commitment to sustainability not only appeals to environmentally conscious consumers but also helps reduce the ecological footprint of pergola production.

In addition to sustainable practices, technological advancements have enabled pergola factory to offer innovative features that enhance the functionality of their products. For instance, many modern pergolas come equipped with integrated lighting systems, retractable canopies, and even smart technology that allows homeowners to control lighting and shading via smartphone apps. These features transform pergolas from simple outdoor structures into multifunctional living spaces.

Trends in Pergola Design

The diversity in pergola design reflects the varied tastes of consumers. Traditional pergolas with simple, classic lines remain popular, but there’s a growing interest in modern, minimalist designs that complement contemporary homes. Features such as retractable canopies, integrated lighting, and smart technology that allows for remote control of lighting and shading are in high demand.

Additionally, there is a trend towards creating multifunctional outdoor spaces. Pergolas are increasingly being designed to support accessories like outdoor kitchens, fire pits, and lounge areas, transforming them into central hubs for entertainment and relaxation.

One of the most notable trends in pergola design is the integration of natural elements. Many homeowners are opting for pergolas that incorporate greenery, such as climbing plants and vines, to create a more organic and tranquil environment. This trend not only enhances the aesthetic appeal of pergolas but also promotes a connection with nature, making outdoor spaces more inviting and serene.

Another emerging trend is the use of mixed materials in pergola construction. While wood remains a popular choice, many modern pergolas incorporate materials like metal, glass, and composite materials to create unique and contemporary designs. This combination of materials allows for greater customization and enables homeowners to create pergolas that complement the architectural style of their homes.

The Impact of Customization

Customization is a significant aspect of the pergola industry. Pergola factory offer a wide range of options, allowing customers to tailor their pergolas to fit their specific needs and preferences. From size and shape to color and material, the possibilities are virtually endless. This level of customization ensures that each pergola is a unique addition to the client’s outdoor space, enhancing both functionality and aesthetic appeal.

One of the key benefits of customization is the ability to create pergolas that cater to specific uses and activities. For instance, homeowners who enjoy outdoor dining can opt for pergolas with integrated lighting and retractable canopies to create a comfortable and functional dining area. Similarly, those who enjoy outdoor relaxation can choose pergolas with built-in seating and shade features to create a cozy retreat.

In addition to functional customization, pergola factory also offer a wide range of decorative options. Customers can choose from various finishes, colors, and styles to match their personal taste and the overall design of their outdoor space. This attention to detail ensures that each pergola is not only functional but also a beautiful addition to the home.

The Future of Pergola Factory

Looking ahead, the pergola manufacturing industry shows no signs of slowing down. As more people seek to maximize their outdoor living areas, the demand for high-quality, customized pergolas will continue to grow. Pergola factory are well-positioned to meet this demand, thanks to their blend of traditional craftsmanship, innovative design, and commitment to sustainability.

One of the key factors driving the future growth of pergola factory is the increasing popularity of outdoor living spaces. As more homeowners seek to extend their living areas into the outdoors, the demand for functional and aesthetically pleasing outdoor structures like pergolas is expected to rise. This trend is particularly strong in regions with mild climates, where outdoor living can be enjoyed year-round.

In addition to the growing demand for outdoor living spaces, the future of pergola factory will be shaped by advancements in technology and materials. For instance, the development of new, durable materials that require less maintenance and offer greater resistance to the elements will enable pergola factory to produce structures that are both beautiful and long-lasting. Similarly, advancements in smart technology will allow for the integration of more sophisticated features, such as automated shading systems and climate control.

Sustainability will also play a crucial role in the future of pergola factory. As consumers become increasingly aware of environmental issues, there will be a growing demand for eco-friendly products and practices. Pergola factory that prioritize sustainability, such as those that use sustainably sourced materials and energy-efficient manufacturing processes, will be well-positioned to meet this demand and gain a competitive edge in the market.

Case Study: A Leading Pergola Factory

To illustrate the impact and potential of pergola factory, let’s take a closer look at a leading manufacturer in the industry, Oscar Shades. Established in 2015, Oscar Shades has become renowned for its high-quality, customizable pergolas that cater to a diverse clientele.

Craftsmanship and Quality

Oscar Shades prides itself on its commitment to craftsmanship and quality. The factory employs a team of skilled artisans and carpenters who work meticulously to create pergolas that meet the highest standards of excellence. Each pergola is crafted from premium materials, such as sustainably sourced cedar and aluminum, ensuring durability and longevity.

Innovation and Technology

Innovation is at the core of Oscar Shades’ operations. The company utilizes advanced design software to create detailed 3D models of custom pergolas, allowing customers to visualize their designs before production begins. This technology not only enhances the customer experience but also ensures precision and accuracy in the manufacturing process.

In addition to design software, Oscar Shades incorporates state-of-the-art machinery, such as CNC machines, to execute intricate designs and ensure precise cuts. This blend of technology and craftsmanship allows the company to produce pergolas that are both functional and visually appealing.

Sustainability Initiatives

Oscar Shades is committed to sustainability and environmental responsibility. The company uses eco-friendly materials, such as FSC-certified wood and recyclable aluminum, in its production processes. Additionally, Oscar Shades has implemented energy-efficient manufacturing practices, such as using solar power and reducing waste, to minimize its environmental impact.

Customization and Customer Satisfaction

Customization is a cornerstone of Oscar Shades’ business model. The company offers a wide range of options, from size and shape to color and material, allowing customers to create pergolas that fit their specific needs and preferences. This level of customization ensures that each pergola is a unique addition to the client’s outdoor space.

Customer satisfaction is a top priority for Oscar Shades. The company provides personalized service, from the initial design consultation to the final installation, ensuring that each customer is satisfied with their pergola. This commitment to customer service has earned Oscar Shades a loyal clientele and a reputation for excellence in the industry.

Conclusion

The rise of pergola factories represents a significant trend in the outdoor living industry. These specialized facilities combine traditional craftsmanship with modern technology to produce high-quality, customizable pergolas that cater to a diverse range of tastes and needs. Through their commitment to innovation, sustainability, and customer satisfaction, pergola factories are transforming outdoor spaces and enhancing the way people live and enjoy their homes.

As the demand for outdoor living spaces continues to grow, the future of pergola factories looks bright. Advancements in technology and materials, coupled with a growing awareness of environmental issues, will drive the industry forward and lead to the development of even more innovative and sustainable products. Pergola factory that embrace these trends and prioritize quality and customization will be well-positioned to thrive in the evolving market.

In conclusion, pergola factory play a crucial role in shaping the outdoor living landscape. Through their dedication to craftsmanship, innovation, and sustainability, they provide homeowners with beautiful, durable, and customizable solutions for enhancing their outdoor spaces. As trends evolve and technology advances, these factories will undoubtedly continue to lead the way in creating elegant and functional pergolas for all to enjoy.

You have noted very interesting details! ps nice web site.Raise your business